Terra Measurements Safeguards 186-Year Old Bridge during Refurbishment with Live and Continuous Structural Data

As of March 2024 data, around 2,928 of the approximately 73,208 council-maintained road bridges in Great Britain are classified as "substandard". This means they are unable to safely carry the heaviest modern vehicles (up to 44 tonnes) and may have weight restrictions or be under increased monitoring. Additionally, more than 67% of UK bridges are over 30 years old.

Terra Measurements, a UK-based specialist in 3D surveying and measurement, were given the ambitious task by Staffordshire County Council to reinforce Branston Bridge: a 185-year-old Victorian structure. To provide a cost-effective but highly reliable way of measuring the bridge, they chose piloting the TotaLite A2.0 sensor. Read more about this refurbishment project on the Staffordshire County Council’s website.

The project focused on monitoring the aging masonry arch bridge, which spans an active rail track. Aging infrastructure such as this suffers from material degradation (e.g., corrosion of steel, concrete spalling) and stress accumulation from increasing traffic volumes and weights. During the works, ensuring the bridge’s structural stability and safety was crucial. With this in mind, the asset owner needed a reliable monitoring solution to track potential deformations and respond quickly to any unusual movements.

Peter Mason, Staffordshire County Council Cabinet Member for Strategic Highways said:

As a local resident, I know the effect of the closure of the bridge has had on the local community. Highways crews have been working incredibly hard on this very complex project, and managed to overcome some unexpected issues to get the job completed. During the works our monitoring equipment picked up that the structure is moving. Engineers will continue to monitor this as traffic uses the bridge. Our engineers are confident in the design of the concrete saddle protecting from excessive movement.

The Challenge

The traditional approach for this type of monitoring relies on manual total station surveys — carried out daily at first and then weekly as the works progress. While accurate, this method is labour-intensive, costly, and poses safety risks, as surveyors must work close to live rail tracks.

To overcome these challenges, Terra Measurements and TotaLite aimed to explore how TotaLite’s automated optical system could reduce site visits, improve data continuity, and provide deeper insight into the bridge’s behaviour throughout the maintenance period while saving costs.

Our Solution

As part of the pilot, first the initial TotaLite A1.0 sensor was installed, and later a TotaLite A2.0 sensor to monitor the bridge’s movement continuously and non-invasively. The system automatically captured positional data of selected optical targets. Over twenty targets in total were fixed to the arch brickwork so that changes in shape could be measured in the fractions of millimeters - a deep level of granularity detected dynamically and in real-time.

TotaLite’s compact design and straightforward setup allowed for quick installation without disrupting ongoing maintenance or rail operations. The pilot focused on evaluating accuracy, stability, and the system’s ability to reveal subtle patterns not typically captured by manual total station measurements.

Terra Measurements firmly believes in the strength of sensor fusion. Within this project, accelerometers provide insight into the dynamic behaviour of the bridge, while routine total station measurements monitor its stability. In similar future projects, TotaLite could act as a real-time alerting system, replacing routine checks. In the event of detected or suspected unwanted movements, manual total station measurements can then be used to clarify and validate the situation.

Fig 1a) TotaLite 2 installed, Fig 1b) Targets projected on the bridge

TotaLite version 1 demobilised.

The Results

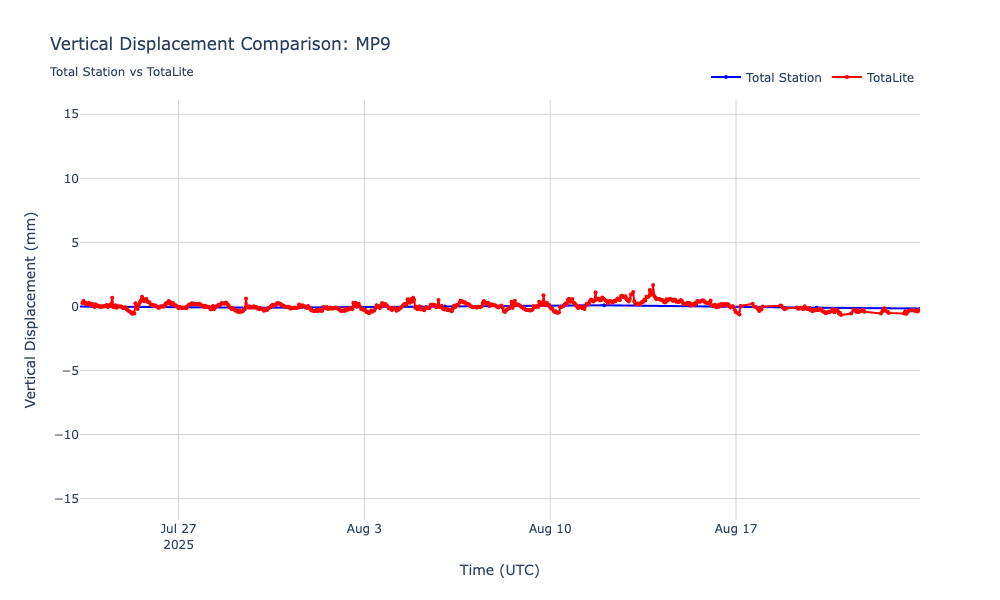

Over the course of the pilot, TotaLite delivered continuous, high-frequency displacement data, enabling the detection of both long-term trends and short-term variations.

The system revealed daily movement cycles linked to temperature changes—behaviour typically missed by manual total station monitoring due to its lower sampling rate. These insights can provide valuable context for understanding normal structural responses versus true deformation events.

While the data showed excellent correlation with total station readings, occasional outliers were observed. Based on these findings, the team recommends using daily median values as the basis for automated alerts—providing a reliable trigger for surveyors to perform site verification when necessary.

Conclusion

The Branston Bridge pilot demonstrated the strength of TotaLite 2 when integrated with other sensors. TotaLite can act as an early-warning system for movements, while manual total station measurements are used to clarify and validate any detected or suspected anomalies. This integrated approach provides a cost-effective way to obtain continuous insights, reduce risk, lower on-site labour requirements, and improve safety by minimising the need for work near live rail tracks.

Key achievements of the project include:

A potential cost saving of up to 65% over the course of the project by eliminating weekly site visits.

A 70% reduction in man-hours and associated travel emissions through the use of an autonomous monitoring system.

Continuous insights into the structural stability of the bridge, delivering a clear competitive advantage over traditional periodic monitoring solutions.

As a result of the excellent collaboration between Terra Measurements and the construction contractors, the railway remained operational throughout the project, significantly minimising disruption to local communities and the wider rail network.